Fiberglass Yarn

Description Fiberglass yarn through drawing, unwinding, doubling and twisting process, which has excellent performance such as strength, good insulation performance, high temperature resistance and small thermal conductivity. It is widely used for insulation material, tubes, electronic industrial fabrics and weaving all kinds of fabrics. | Fiberglass yarn is electrical insulation materials, electronic industrial fabrics ,tubes and other industrial fabric raw materials. It is widely used for weaving all kinds of fabrics in the scope of reinforcement, insulation, corrosion resis-tance,heat resistance and so on. | Fiberglass yarn is made from 5-9um fiberglass filament which are then gathered and twisted into one finished yarn. | Glass fiber yarn is necessary raw material for all kinds of insulation products, engineering material and electric industry. Ending product of Glassfiber yarn: such as, electronic grade fabric, fiberglass sleeving and so on, E glass twsited yarn is characterized by its high strength, corrosion resistance, heat resistance, low fuzz and low moisture absorption. |

|

Fiberglass Roving

Description Fiberglass Roving is made up of parallel filaments or bundles of parallel monofilaments.Non-twist roving can be divided into non-alkali glass roving and medium alkali glass roving according to the composition of glass.The diameter of fiberglass used to produce glass roving ranges from 12 to 23 m.The number of roving yarns is from 150 to 9600 (Tex).Twist-free roving can be directly used in some composite material forming methods, such as winding and pultrusion technology. Because of its uniform tension, it can also be woven into twist-free roving fabric. |

Chopped Strands

Product Description |

|

|

|

| Chopped Strands for Thermoplastic are based on silane coupling agent and special sizing formulation, compatible with PA,PBT/PET, PP, AS/ABS, PC, PPS/PPO,POM, LCP;

E-Glass Chopped Strands for thermoplastic are know for excellent strand integrity, superior flowability and processing property, delivering excellent mechanical property and high surface quality to its finished product. |

Wet Chopped Strands

Product Description |

|

|

|

| Wet Chopped Strands are compatible with unsaturated polyester, epoxy, and phenolic resins. | It is used in the water dispersion process to produce wet light weight mat. | Wet Chopped Strands are formed by chopping continuous fiber to a certain length, mainly used in gypsum industry. |

E-glass Chopped Strand Mat

Product Description |

|

|

|

| Chopped Strand Mat is a kind of reinforcing products which made from randomly distributed chopped strands with certain length held together by a powder or emulsion binder. | Applications |

|

|

|

| Chopped strand mat is suitable for hand lay-up, molding process, mechanical forming process etc., The product is widely used in different areas of FRP, automobile parts, boats, bath equipments, chemical storage tanks, pipes, construction materials, desks, etc. |

Fiberglass Cloth

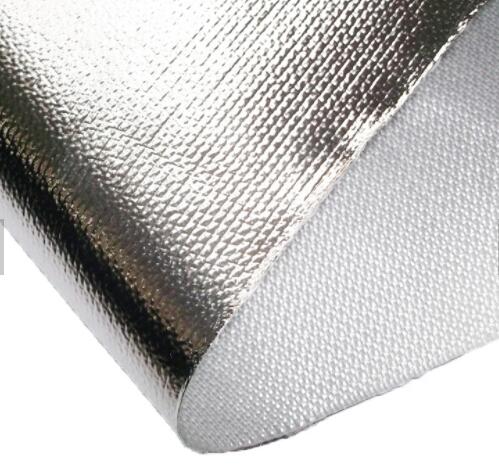

Product Introduction | Fibreglass cloth is a kind of economical insulating material which is light and easy to install. This material has excellent performance of sound absorption and good elasticity. It is mainly applicable in heat & sound insulation of office building, hotel, public place of entertainment,inner wall, ceiling and roof, airconditioner room and cold storage room. It can apply on the surface of glass wool slab, mineral wool slab, rockwool slab, fiberglass blanket. It can with aluminum foil. |

| Glassfiber Needled Mat

Product Introduction | GLASSFIBER NEEDLED MAT is an advanced material for air cleaning and thermal insulation made by cutting continuous glass fibers into given length and then felting them through a process of filamentizing, napping and needling. Characterized by high temperature resistance, good thermal insulation, superior acoustic absorptivity and high efficiency of cleaning tail gas. It has found wide application in mechanical, electrical, chemical, metallurgical, petroleum, coal, building and traffic industries, suitable for the use as sandwiched heat and sound insulation system in automobile, ship, and train carriages. When treated with a ternary rare-earth cleaning catalyst, it is an ideal material for tail gas cleaning and sound deadening for cars and motorcycles. |

| | Fiberglass mesh (Fiberglass net)

Fiberglass mesh is mainly alkali-resistant fiberglass fabric, it use the C /E glass fiber yarn (main ingredient is a silicate, good chemical stability) through a special weaving technique, then by the anti-alkali and reinforcing agent etc high temperature heat finishing treatments. It's ideal engineering material in construction and decoration industry! | 1.Good chemical stability: Alkali-resistant, acid-resistant, waterproof,, cement erosion-resistant, and other chemicals' corrosion resistant; and strong resin bonding, soluble in styrene. | 2.Outstanding craftsmanship include coating enough alkali-resist glue, our coating glue is produced by Germany BASF which can keep 60-80% strength after test in Naoh 28days later, so that guarantee high strength, high tensility, light weight. | 3.Our fiberglass yarn is supplied by Jushi Group which is the largest producer of fiberglass yarn in the world like Saint Gobain, | it's 20% extra strong strength and beauty surface than normal fiberglass yarn! | 4.Strength retention rate> 90%, elongation <1%, the durability of more than 50 years | 5.Good dimensional stability, stiffness, smoothness an difficult to shrink and deformation, good positioning property.. | 6.Good impact resistance and not easy to be teared. | 7.Fire resistant, thermal insulation, sound insulation, insulations etc. |

|

Glass fiber product

|

|

|

|

Non-flamable, anticorrosion, high strength, good electrical insulation, all thiese are the specific characteristics of glass fiber, thus becomes the most necessary base materials to be used in the fields of electrical, chemical, aerospace, shipbulding, autombile, constructional decoration and the hi-tech industries as well |

|

|

|

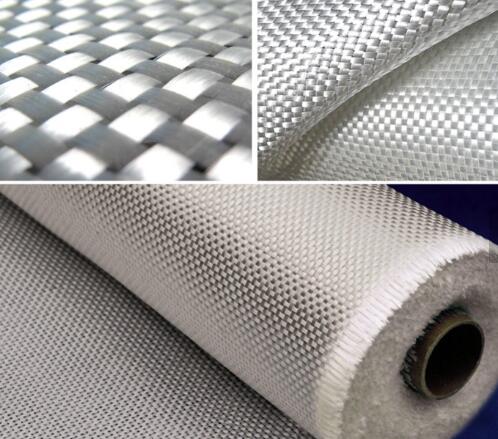

GLASS FIBER FABRIC |

|

To change the weaving structure with warp yarn as well as weft yarn glass fiber fabric is primarily of three kinds, namely plain weave, twill weave and stain weave. And from these three fundamental weaves on someth other structures can be derived. |

|

|

|

|

|

Chopped strand mat |

|

Chopped strand mat is the important non-woven strength material to make prototype by hand using glass fiber steel. The material was compounded by short glass fiber dispensing evenly and the powder or emulsion. Short cutting felt products are used widely in chemical antiseptic pipe , ships and boats, vehicle spare parts, insulation material, sanitary tools, chairs, architecture and all kinds of products of glass fiber steel. |

|

Main Specification: Type of glass: E-glass and c-glass. Area weight: 100g/m2-900g/m2 |

|

Binder: powder or emulsion. Weight per roll 30k-70kg.Width:300mm-2600mm. |

|

|

|

Fiberglass needled felt |

|

Fiberglass needled felt is an advanced material for air cleaning and thermal insulation made by cutting continuous glass fibers into given length and then felting them through a process of filamentizing, napping and needling. Characterized by high temperature resistance, good thermal insulation, superior acoustic absorptivity and high efficiency of cleaning tail gas. It has found wide application in mechanical, electrical, chemical, metallurgical, petroleum, coal, building and traffic industries, suitable for the use as sandwiched heat and sound insulation system in automobile, ship, and train carriages. When treated with a ternary rare-earth cleaning catalyst, it is an ideal material for tail gas cleaning and sound deadening for cars and motorcycles. |

|

|

|

|

|

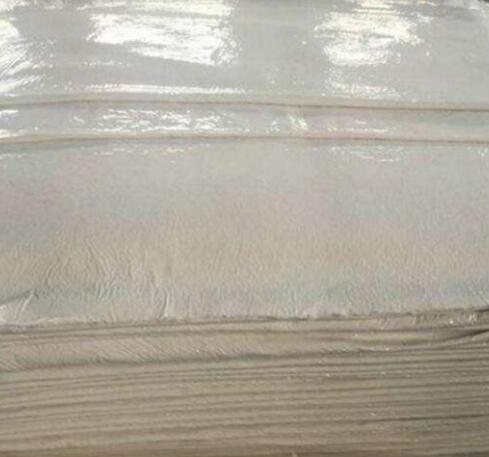

Woven roving |

|

The woven roving is a kind of stable construction, fire resistance, high temperature resistance, good heat dispensing, corrosion resistance, high temperature resistance industrial material. |

|

Main Specification: Type of glass: E-glass and c-glass .Area weight: 200g/m2-1200g/m2 |

|

Width: 200mm-1450mm |

|

|

|

|

|

|

|

Fiberglass mesh |

|

Fiberglass mesh is made from glass fiber and processed by special technology. Function |

|

High strength, alkali-resistant, acid-resistant, strong performance compounded with resin, easy to solute in styrene, perfect position, ideal for strengthening material. |

|

Main specification: 2x2mesh/inch-14x14mesh/inch Area weight 45g/m2-450g/m2 |

Others: Class fiber cloth, Class fiber tape, Class fiber rope, Class fiber mats...

|